About Vacuum Pressure Impregnation

About Vacuum Pressure Impregnation

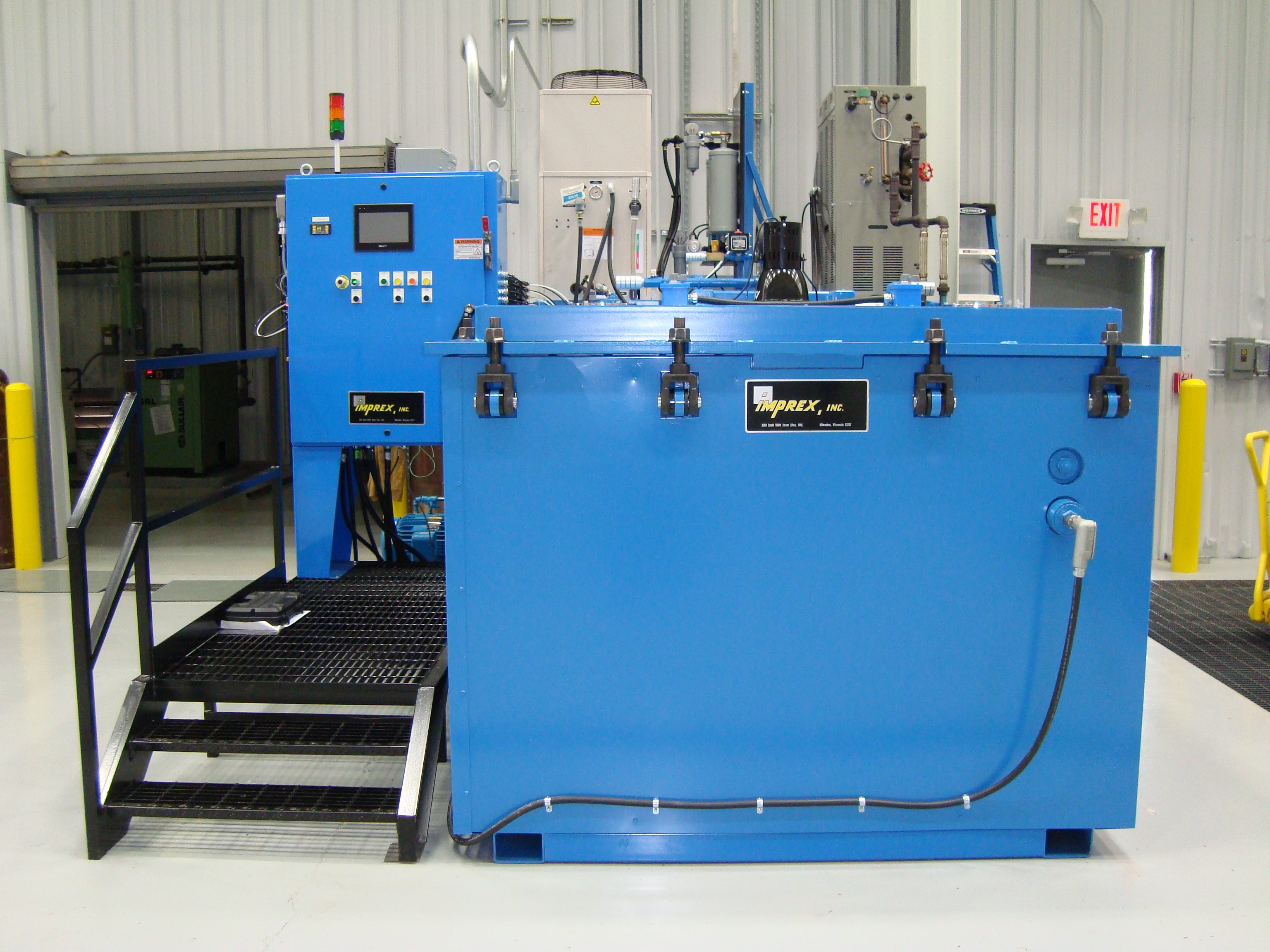

Vacuum Pressure Impregnation (VPI) encapsulates motor stators and rotors with a varnish or resin. The process insulates and seals the porosity of the part.

Vacuum Pressure Impregnation Process

1. Pretreatment: The part is preheated in an oven.

2. Dry Vacuum Step: The part is placed in the pressure vessel, and the cover is closed. The vacuum is pulled to remove air or until a specified vacuum is achieved. This is the most critical step to ensure the part is fully encapsulated (Image 2).

3. Wet Vacuum Step: The transfer valve is opened, and the resin or varnish fills the impregnation chamber while under vacuum.

4. Pressure: The vacuum is released, and pressure is applied for the resin or varnish to penetrate the voids in the part entirely.

5. Release Pressure: Return unused resin or varnish to the holding tank.

6. Cure: The part is removed and placed in the customer's oven for curing.

benefits of Vacuum Pressure Impregnation

1. Improve power output

A fully enclosed part leads to good heat transfer, keeping the electricity within the wires. This results in better part performance.

2. Contamination resistance

Contamination penetrates small openings in the unsealed insulation and produces a conducting path between turns or to-ground. Since VPI fully encloses the part, VPI ensures no risk of contamination.

3. Reduce coil vibration

The most common failure in motors is abrasion. Vibration causes wear and chaffing, leading to a part no longer being able to withstand voltage. Having a part enclosed with VPI serves as an adhesive between the motor strands as it turns. This reduces the risk of coil vibration.