About Vacuum Impregnation

About Vacuum Impregnation

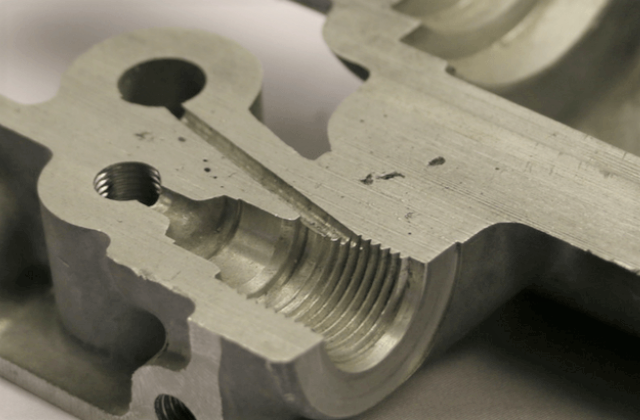

Porosity is inherent to many manufacturing processes. The porosity will create a leak path if it is interconnected. Depending on the size and placement can allow fluids or gases to seap out of the part while under pressure.

Vacuum impregnation is the best way to seal leak paths. By sealing the leak path, parts can function as intended.

Vacuum Impregnation Process

Markets We Serve

- Automotive

- Aerospace

- Defense

- Industrial

- Medical

Materials We Seal

- Aluminum Die Castings

- Brass

- Electronics

- Graphite

- Iron

- Overmolded Electronics

- Powder Metal

benefits of Vacuum Impregnation

By sealing leak paths, vacuum impregnation salvages parts and improves quality. It is also used in powdered metal to prevent corrosion and improve machinability. Impregnation is also utilized before electro-plating to avoid bleedout from acid etches and electrolytes absorbed into porous areas that are sealed in by subsequent plating.