Electronics Impregnation

| Process | Dry Vacuum and Pressure Wet Vacuum |

| Sealants Used | Anaerobic |

| Maximum Part Size | 34" diameter, 23" heights |

| Sealant Specification | MIL-I-17563C |

| Process Specification | MIL-STD-276A |

Proud of our Workmanship.

And it Shows.

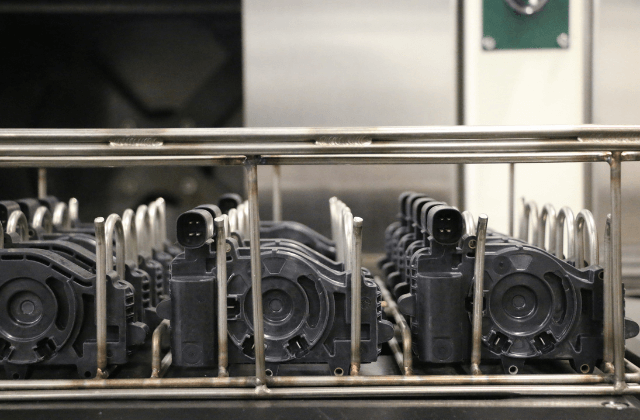

Imprex specializes in electronic and overmolded impregnation. Customers trust Imprex to seal their parts to protect them from moisture, humidity, solvents, fluxes, and corrosive agents.

Why Choose Our Services

1

Range of Equipment

No need to invest in equipment of your own; we have the right system for your job, ready to go. Custom requirements are no problem.

2

Quality

Our quality team and processes ensure excellent results. When customers send parts to Imprex for electronics impregnation, we take care of everything, and do it right the first time.

3

Customer Service

Our long-time employees know how to answer your questions and find solutions quickly.4

Experience

With over 50 years of experience, we know how to process tricky parts. We take pride in being the best in the industry.

Benefits of Vacuum Impregnation

Porosity is inherent to parts, and interconnect porosity may form a leak path. Unless sealed, this leak path will cause the part to fail if it needs to be pressure tight.

Vacuum impregnation seals internal leak paths, and allows a part to be pressure tight. The process allows manufacturers to use parts that would otherwise be scrapped.